1 juillet 2025

Our Equipment

Our means of production

Our machines are updated regularly in order to maintain quality in our realisations. Theses updates are necessary to ensure the quality requested by our customers.

MILLING UNIT

GROB G350

Horizontal machining center with 5th axe – X 600 Y 770 Z 805 – iRNC530 with 34 tools

VICTOR VCA110

X 1100 Y 600 Z 560 – TNC620 with 32 tools

HURON VX12

X 1200 Y 600 Z 610 – TNC620 with 20 tools

YCM XV560

X 560 Y 410 Z 450 – TNC620 with 20 tools

NXV 560A

X 600 Y 410 Z 450 – TNC620 with 20 tools

VERNIER FV340CN

X1030 Y320 Z465 – TNC320 with 4th axe

MIKRON UME 710

X 710 Y 630 Z 500 – TNC 360

VERNIER DB420

X 1120 Y420 Z620

Ernault Somua ZHV1

X 710 Y 270 Z 400

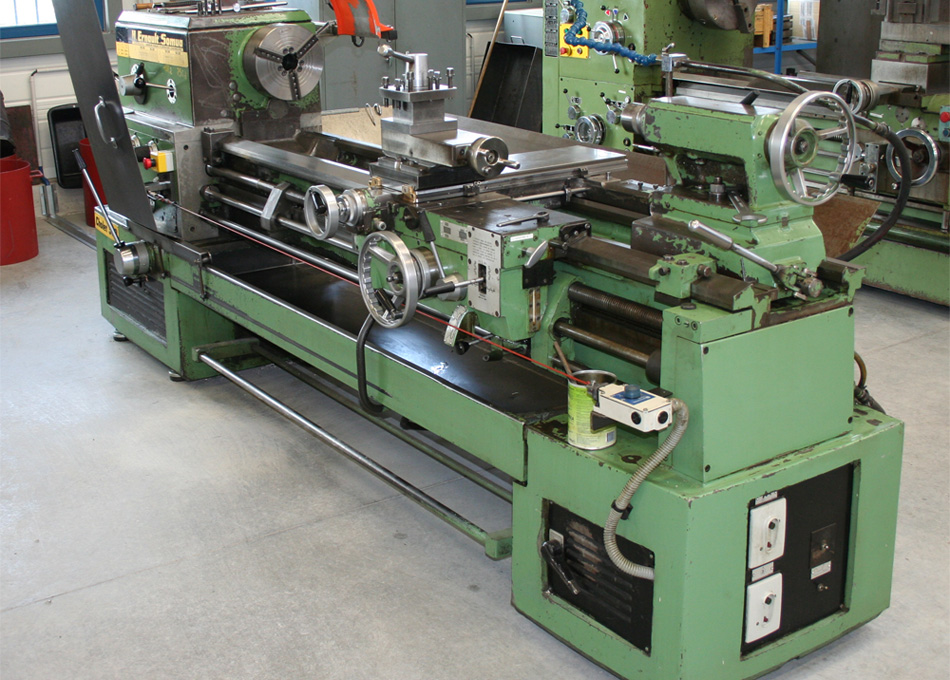

LATHE UNIT

JOHNFORD ST130

4 axes (C and Y) – Motorized tools – Ø950 x 3000 mm – Ø139 in spindle

DMG MORI CTX510 n°2

4 axes (C &Y) – Motorised tools – Ø90 in bar feeder

DMG CTX510V4

4 axes (C &Y) – Motorised tools – Ø90 to Ø400

DMG MORI CTX510

4 axes (C and Y) – Motorized tools – Ø65 in bar + LNS bar feeder

DMG CTX450

4 axes (C et Y) – Motorised tools

DMG CTX310

3 axes (C) – Motorized tools – Ø50 in bar

CAZENEUVE OPTIMAX

3000 mm lengh max – Ø450 to Ø720

CAZENEUVE OPTICA

Ø590 x 1100

CHOLLET 550

Ø500 x 1600

UNIT TOOL WORSHOP

JAKOBSEN-SJ-1026

Plan rectification X650 Y400 Z350 – Magnetic plate 250×600 mm

Excetek V650G

Wire EDM X650 Y400 Z350

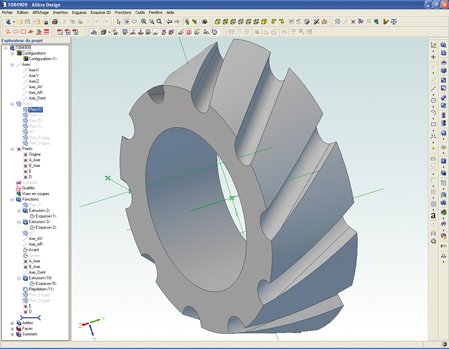

IT means

- 3D CAD

- CAPM with a codification of your products

- Real time production monitoring

Control equipement

- Three-dimensional measuring machine ZEISS CONTURA (Capacity: 700 x 1000 x 600 mm)

- Dedicated air conditionned control room

- TESA Heigh Gauge

- Dedicated control tools with COFRAC certification

- Hardness control (HRc)

- Roughness control

Quality control

- Final control of the production

- Tracability of production with CAPM

- Labelling of your product from raw material reception to final expedition